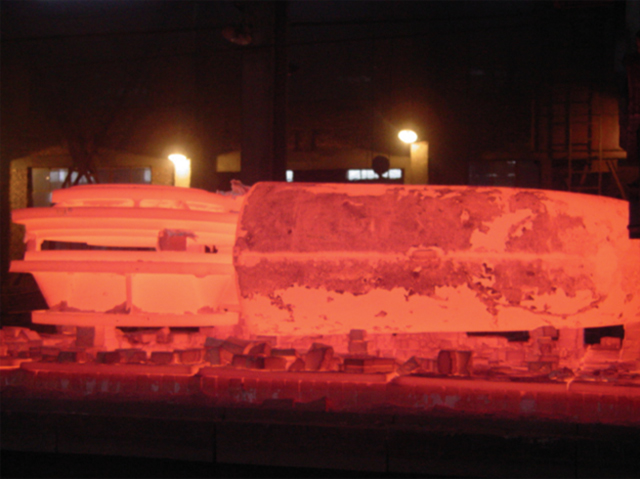

Big Size Castings

Big size castings:

Our big size casting foundry covers an area of 60,000 square meters and a building area of 23,000 square meters. There are more than 660 employees, including 180 senior technical personnel and 480 high-quality technical personnel. The company is a company specializing in the development and manufacture of various metal wear-resistant materials required by industries such as mineral processing, metallurgy, energy, building materials, etc. The main materials of wear-resistant products are Cr27, Cr20Mo2Ni1, Cr25Ni20, Cr34, hard nickel 1#-4# and other high chromium Alloy, the main products include slurry pumps, desulfurization pumps, boiler feed water pumps, river dredging pumps, etc. The pump company has an annual output of 30,000 tons.

Our production scale and product quality are in a leading position in the same industry.

1. Casting capability

We have melting equpment:

1set 10Tons electric arc furnace,

5sets 10Tons intermediate frequency electric furnaces,

5sets frequency electric furnaces,

6sets 5Tons intermediate frequency electric furnaces,

2sets 2Tons intermediate frequency electric furnaces,

and 2sets 1Ton intermediate frequency electric furnaces.

The largest single piece casting can reach 50 tons.

2. Heat treatment capacity

The heat treatment equipment includes: 4sets desktop resistance furnaces, 6sets bell-type heat treatment furnaces, 6sets gas heat treatment furnaces, which can heat treat products such as grinding rolls and grinding tiles

3. Machining capacity

Strong machining capability, with 1set 12-meter CNC vertical lathe, 1set 8-meter CNC vertical lathe, 1set 5-meter CNC vertical lathe, 6sets 3.5-meter vertical lathes, 2sets 2.5-meter vertical lathes, and 12sets 1.6-meter vertical lathes , 16 sets of 1.25m vertical lathes, and supporting various boring machines 4 sets , 20 sets of horizontal lathes, 6 sets of rocker drilling and more than 90 sets of various lathes。

4. Inspection Capability

The testing equipment includes direct-reading spectrometer, ultrasonic flaw detector, universal material testing machine, impact testing machine, metallographic microscope, desktop hardness tester and various measuring tools imported from Germany.